Leister BITUMAT B2 Welding Machine 75mm/100mm 230v 32A inc safety kit

Hire from £392.00

Welding modified bitumen sheeting (SBS, APP) with the flameless BITUMAT B2 230v welding machine is much safer than welding with an open flame. Weld strength is significantly better and the single step process makes welding more economical. Available in 75mm or 100mm nozzle & roller widths.

Please note we hold a £500 refundable deposit for the duration of your hire.

- Description

Description

The flameless Leister BITUMAT B2 welding machine uniformly welds modified bitumen (SBS, APP) at high speeds of up to 12 metres/minute. Not only is the welding process much safer than welding with an open flame, there are less logistical issues of carrying large gas canisters around, running out of gas and, adhering to stringent HSE requirements and ACOP best practice when dealing with naked flames – e.g. inspecting for flammable material before the job (safe2torch), and for any signs of continuing combustion 3-4hrs afterwards.

An added benefit of using the BITUMAT B2 welding machine is its green credentials. Reducing the use of fossil fuels in construction can only have a positive impact to the environment, and the flameless BITUMAT B2 does this to great effect.

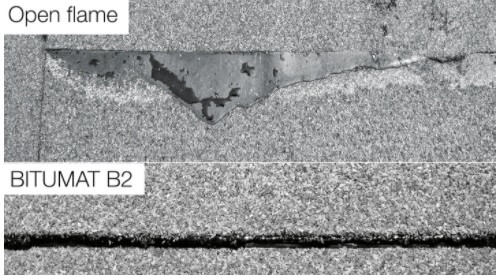

However, the main advantage by far is the stronger, and more consistent weld quality (see image below).

Welding modified bitumen (SBS, APP) with the BITUMAT B2 produces considerably improved welding results when compared to flame tools, which can often produce inconsistent results due to variations in the weather or gas supply.

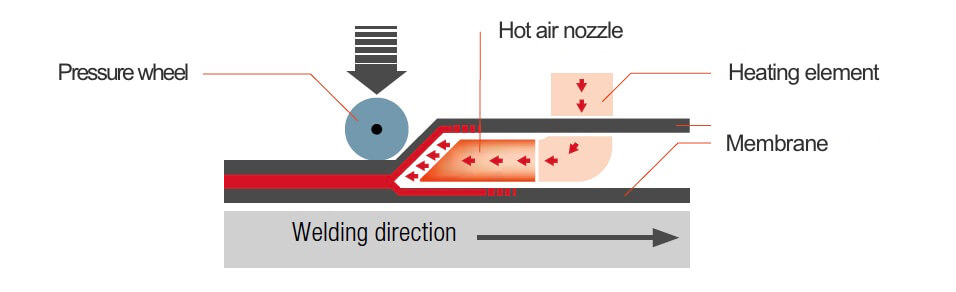

The BITUMAT B2s nozzle produces an air dam of hot air, which is variably controlled between 20 – 650ºC. This air dam produces a mass of hot air at a specific regulated temperature, at the leading edge of the seam as it is being formed which creates a controlled amount of thermal energy sufficient to weld the material but not enough to cause run-away combustion.

Key Features

- Flameless welding of modified bitumen

- Welds modified bitumen sheeting (SBS, APP)

- Welds up to 12 metres/minute

- Welds material up to 6mm thick

- 75mm or 100mm Welding Nozzle Width

- Temperature range between 20 – 650ºC

- No shrinking of insulation due to integrated air dam

- Accurate Temperature Control gives uniform welding results

- Press & turn controls with saved settings

- Constant drive & regulated electronics

- Requires only one user to efficiently weld seams (torch welding requires two)

- Power up to 6.7kW

- Current of 32A

- 230V

- Weight 40kg

- Comes in a sturdy storage case (750 x 555 x 450mm)